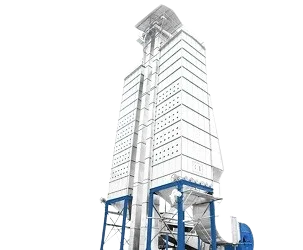

Dryer |

Effortless drying of grains, rice, and pulses with advanced moisture control. This energy-efficient dryer delivers consistent results for seamless milling processes.

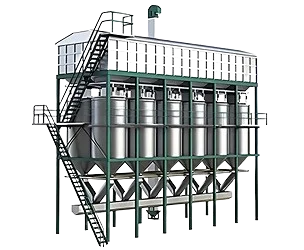

Parboiling Plant |

Enhance grain quality with our efficient Parboiling plants. It ensures even steaming, reduces breakage, and improves rice texture, while preserving nutrition. Perfect for streamlined, high-performance milling

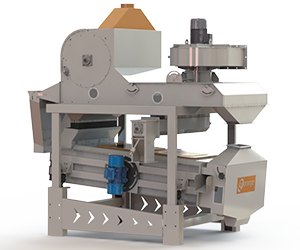

RAW PADDY PRE-CLEANER |

The Raw Paddy Pre-Cleaner is a robust machine designed to separate harvested paddy from large unwanted materials such as hay, big stones, mud balls, and unwanted soil. Utilizing traditional methods ensures efficient and effective output.

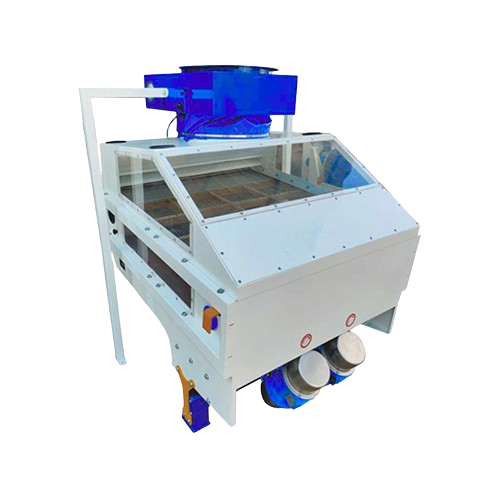

VIBRO PADDY CLEANER |

The Vibro Paddy Cleaner is built to separate harvested paddy from smaller impurities like dust, small stones, mud balls, and unwanted soil. It operates using traditional methods to achieve efficient and effective results.

PADDY DESTONER |

The Paddy Destoner removes stones, sand, and clods from grains such as rice, paddy, and beans. It operates on the principle of vibrating an inclined sheet at a specific angle, causing heavier particles to move upwards while using a suction mechanism to remove dust and lightweight particles.

PADDY SEPARATOR |

The Paddy Separator Machine separates brown rice from unhusked paddy. It works based on the differences in specific gravity, granularity, and friction coefficient between paddy and brown rice. Using a special separating tray, it continuously screens the mixture, ensuring stratification.

PADDY CLEANER CUM DESTONER |

The Paddy Cleaner Cum Destoner is designed to minimize power consumption and save mill space. This robust yet simplified machine combines the functions of a pre-cleaner and a Vibro Paddy cleaner, removing stones, straws, mud balls, fine soil, and dust with low power consumption.

PADDY HUSKER |

The Pneumatic Sheller is a compact, high-efficiency machine designed to remove the husk layer from rice. It operates on the principle of rubber-grain rubber frictional contact, effectively husking the paddy without causing significant damage to the grain. HUSK SEPARATOR

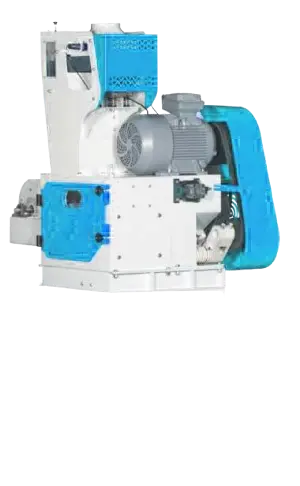

ABRASIVE STONE POLISHER |

The Whitener, also known as an abrasive polisher, removes the bran layer from rice using rough stones. The rice is gently passed through an abrasion chamber lined with silicon carbide stones, transforming brown rice into white rice. The removed bran is collected by an external suction blower.

WATER JET POLISHER |

Silky polishes the outer surface of the rice with water through a rotating camshaft. It features an inbuilt water atomizer that sprays water evenly over the rice, which then passes through the camshaft roller. This combination of friction polishing and water creates a glossy finish on the rice.

HUSK SEPARATOR |

The Husk Separator efficiently separates brown rice, rice husk, and dust. Its aerodynamically designed structure ensures optimal performance.

HUSK ASPIRATOR |

The Husk Aspirator is designed to remove lightweight husk and dust particles from the grain stream, ensuring cleaner rice output.

RICE SIFTER |

The rotary sifter is designed to separate broken rice depending on its thickness. The rotary sifter comes with 5 trays making rice categories in 5 different sizes.

THICKNESS GRADER |

Thickness Grader is designed specially to segregate/ classify types of rice concerning their thickness. Thickness grader requires a very minimal amount of power for its best performance.

LENGTH GRADER |

Length Grader is a specialized machine for segregating head rice from a mixture of broken rice. Highly efficient segregation stars from High-quality embossed sheets and calculated motor speed.

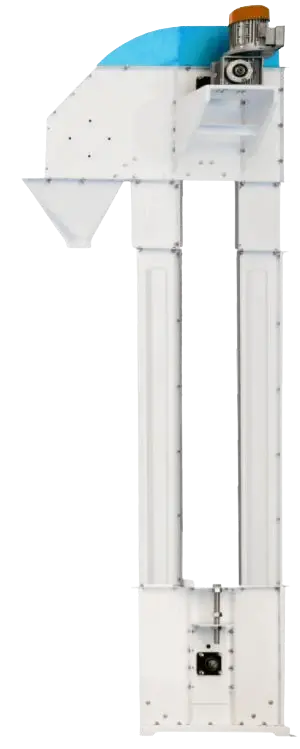

GRAIN FEEDER |

Elevator is one of the most essential products in material handling and movement. Elevators are operated using a worm gear fixed motor and run with a calculated surface speed for better output performance. Elevators have especially taken care in improving tonnage and maintaining product quality by repeated research and development from various aspects. 1) Broken reduction 2) Dust suction 3) Accelerating chute 4) PLC-supported design 5) Food grade quality belt 6) SS or Silicon Decelerator 7) Imported Industry Quality Bearing 8) Elongation Scale

SINGLE HEAD |

Hargovind rice machinery solution introduces the efficient MM - S75NC packing machine. Its compact design allows it to fit directly under the hopper, saving space with a height of just 1 foot and 9 inches. The machine measures weight with the bag, eliminating the need for manual weight entry.

DOUBLE HEAD |

Hargovind rice machinery solution presents a high-speed, accurate, and user-friendly MM - D75NC packing machine. Incorporating state-of-the-art technology, it features an imported load cell that requires minimal calibration. Users can calibrate the weighing acceptance level themselves. This model includes many exciting features designed to meet user requirements.

TRIPLE HEAD |

Hargovind rice machinery solution offers the MM - T75HC, the fastest and most efficient packing machine. Utilizing three individual weighing bin mechanisms, it achieves a 75% faster bag-filling rate compared to single-head machines. The advanced imported load cell needs only a few calibrations throughout its lifetime, making the MM - T75HC ideal for customers with large loads that need to be packed, stitched, and loaded quickly.